We build shrink packing machines for all products below

What is your product or industry?

Select your industry below

Machine spotlight

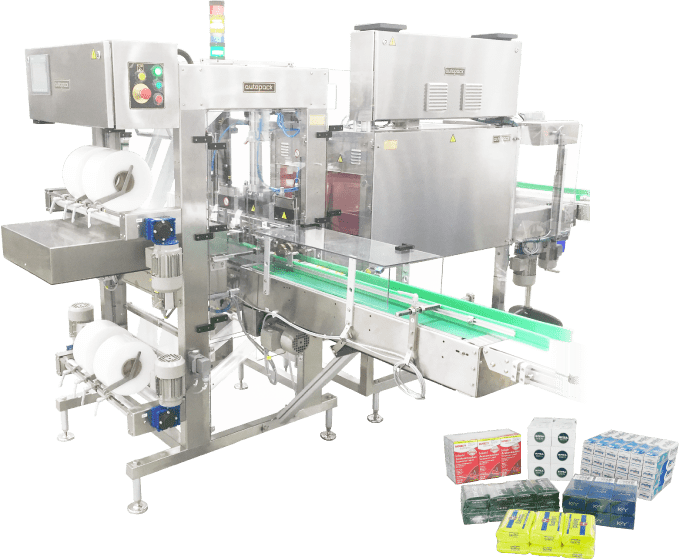

- Speed up to 40 cycles/min, i.e. 120 packs/min with 3 track operations

- Bottom ovelap seal for printed film

- Tooless and quick sizes changeover,

- One of the world fastest overlap machine using conventional motors (no-servo drives used) !

Autopack SLV is designed for stacking and shrink wrapping of flat rectangular objects, such as cartons, soap cakes, toothpaste, reams of paper, shoe boxes and many others. All stainless steel GMP finish makes it an ideal Shrink Wrapper for pharmaceutical and cosmetic industries.

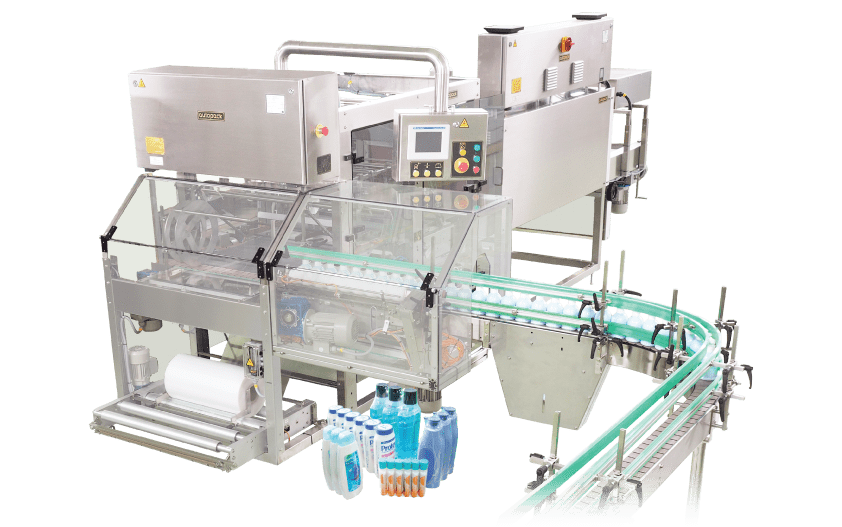

- Speed up to 45 cycles/min, i.e. 135 packs/min with 3 track operations

- Bottom overlap seal for printed film

- Infeed with feedscrew for preorientation of bottles

- User-friendly equipment with quick sizes changeover

- One of the world’s fastest overlap machines using conventional motors (no-servo drives used) !

Our customers

Autopack machines are popular among small businesses because of their affordability and simplicity. Large businesses also trust Autopack to deliver machines meeting high standards of performance, reliability, and support.

Recent News

Promotional cards enclosed in shrink wrapped bundle packs are often used by marketing to entice customers to purchase their brand with bonus offers. In general, card insertion is done manually which requires both, operator skill to achieve satisfactory result and care to avoid contact with hot or moving parts. Autopack has recently developed an addon Module to its 62SLA, UHT multipacking machines for Tetra Briks. The inserter can currently handle cards similar size to visiting card at speeds up to 30 cycles per min.

As automation replaces manual packing at the end of line, it also removes final inspection of pack integrity. Most packaging machines may at some time produce an inferior pack due to operator error or machine malfunction.

If the line also includes automatic palletizer, this may go unnoticed until the pack is delivered to enduser, leading to claims and returns, hence manufacturers are looking for ways to eliminate or minimize this problem.

The first course of action is to isolate and eliminate the root cause. But sometimes such faults result from cumulative process errors on line, are very infrequent and hard to trace. In such cases the only way to ensure high degree of elimination is by final check at the end of the line.

Depending on packing process, for example, case packing, one can use a check weigher with rejection station to eliminate short count. In case of Shrink bundle packing, visual inspection may be better and perhaps less expensive option.

Autopack have recently developed a visual inspection and rejection station using Artificial intelligence (AI) Camera. The device can detect missing cap, deformed shape or missing bottle from the Shrink wrapped bundle.

The system has so far proven reliable and Autopack will soon offer it as a standard option for Autopack range of Shrink, Tray, and Case packing.

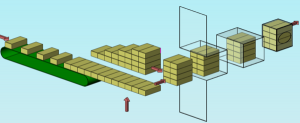

Autopack has extended its fast Staircase collator principle to stacking reams of paper. Generally, reams of paper are packed in a stack of 5 inside carton box or shrink wrapped.

Since paper ream production lines are fairly fast, stacking the reams one by one in a single column would be to slow.

To meet the line speed 100 reams per minute, Autopack has designed a heavy duty collator which in a single cycle converts horizontal layer of 5 reams into a vertical stack of 5.

The stack is subsequently ejected for shrink wrapping resulting in a tight pack, ready for stacking on pallet.

Recent Articles

Due to Covid-19, many manufacturers with liquid and cream filling lines, have switched to producing and packing sanitizers. Since sanitizer solutions contain high percentage of alcohol, making them flammable, one must take precautions to reduce risk of fire or explosion.

Once filled and capped, chances of ignition are lesser, however, during the packaging process, jam and spill can occur which needs to be handled in appropriate way.

In case of heat shrink packing, the bottle or tubes may be left inside the hot Shrink Tunnel for long enough to cause leak and ignition.

Besides operational jams, power shutdowns and component failure can also lead to product being stuck inside the hot chamber.

Autopack Shrink Packing systems can be fitted with many options to reduce chances of fire or explosion for packing flammable substances.

Depending on level of danger, these range from simple guides or handles to remove the product from tunnel, to more sophisticated systems of evacuating hot air or even flooding the chamber with inert gas.

During this difficult period of Corona Pandemic, Autopack People offer free advice to companies using Bundle Shrink packaging to help them reduce the risk. For Autopack machines there are retrofit kits available which can be fitted by the customers to their shrink tunnels. So please contact us if you need advice.

Recently installed Autopack Machine for Shrink Packing of tapered Ice cream tubs.Totally Cool Icecream in USA is able to shrink wrap Ice cream tubs without any cardboard support. By inverting the tubs one up one down the Tubs form a stable group resulting in a solid pack after shrink wrapping.

Autopack welding bar type Shrink Wrappers can wrap up to 30 bundles per min, however the final packing speed depends on how quickly one can prepare the bundle before the wrapping process.

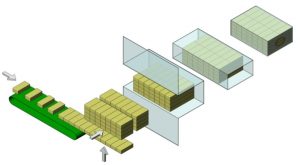

When packing cartons such as tooth paste, pharma tablets, soaps cakes etc, the collation is generally prepared by a vertical collator. In a typical vertical collator cartons accumulate on top of a lifting plate which elevates the cartons to higher level, where they are retained by suitable latches. The process is repeated until preset packing quantity is made after which the group is transferred into the sleeve shrink wrapper.

The speed of preparing the bundles is dependent on the maximum number of lifts the collator can make and the stacking format. A typical pneumatic collator can make approx 40 lifts / min.

So if we are packing 10 cartons in a 5×2 format (5 across and 2 high) we can make approximately 20 complete packs per min ( 200 cartons per min). However some cartons, due to their geometry, need to be packed 2×5. In this case the stacker has to lift 5 times to make one complete bundle which drops the speed to 8 packs per min.

To speed up the collating process Autopack have introduced a unique “Staircase” collator which can stack narrow and tall packs, much faster than traditional bottom up stacker.

Why Autopack ?

Down to Earth

We strive to make good machines. To solve problems. That’s it. We aren’t in the business of using impressive words or selling you something you don’t need.

Talk to us. We get straight to the facts.

International sales and service

We deliver solutions all around the world. Our offices and agents are listed here.

Many staff in our manufacturing base in Thailand come from Europe, Australia, or Southeast Asia, and speak a variety of languages.

Innovative design

We don’t just copy the latest trends. Our engineers think differently to get better results at the lowest cost. It is easy to design complex solutions, but we believe simple solutions are better.

Try one of our popular innovations—our film cost calculator.

Quality and Experience

We have 35 years’ experience in the packaging industry. We use the highest quality parts and workmanship to minimise downtime and keep machines serviceable for a long time. Some of our customers still use our machines that are decades old!